For the first time in North America, the German Fuel Cell Cooperation (GFC) will present a highly productive, interface-tuned complete line for the production of metal bipolar plates at the Hydrogen Technology Conference & Expo 2023. The event will take place from 28 to 29 June 2023 at the NRG Center in Houston, Texas, USA and the GFC will exhibit at booth 1270.

Perfect tool to meet the ambitious goals of the Inflation Reduction Act

By combining their respective competencies, the three German companies VON ARDENNE (Dresden), Weil Technology (Müllheim) and ZELTWANGER (Tübingen), as partners in the GFC, offer manufacturers of fuel cell systems and electrolyzers fully comprehensive know-how for the efficient production of metallic bipolar plates.

The concept of a fully coordinated production line plays a pioneering role in the market. And, with an annual production capacity of several million bipolar plates, it serves the current needs of the industry. Thus, the production line perfectly meets the requirements for achieving the ambitious goals of ramping up the production of green hydrogen and fuel cell vehicles, motivated by the tax credits from the Inflation Reduction Act.

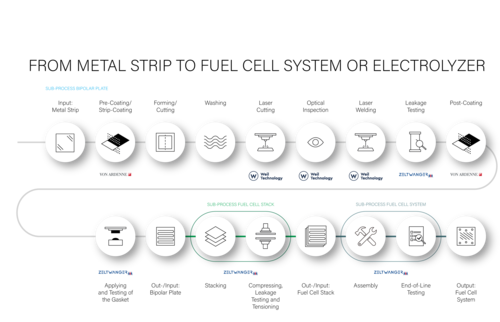

The long-standing expertise of the three mechanical engineering companies covers all process steps. And the joint development and careful coordination of the line concept enables smooth transitions at the interfaces of the individual production steps. To this end, the line processes pre-stamped half-plates made of stainless steel or titanium. In a first step, these are welded into bipolar plates, which are then leaktested before they receive a PVD coating to functionalize their surface.

With their extensive shared knowledge of the complex value chain and high degree of specialization in the sub-processes, the three GFC companies can develop a customized production line together with their customers. These specification-compliant production lines optimally integrate the various customer-specific approaches.

VON ARDENNE contributes its expertise in the development and manufacturing of vacuum coating systems used to functionalize surfaces of metal strip (pre-coating) or bipolar plates (post-coating). Weil Technology is an experienced supplier of equipment in the field of laser cutting and laser welding of metallic bipolar plates. ZELTWANGER provides the equipment for automated assembly and testing processes as well as leak testing into the production chain.

GERMAN FUEL CELL COOPERATION – Booth and Contact

Date: June 28 - 29, 2023

Booth: 1270, NRG Center, Houston, Texas

Web: www.fuel-cell-cooperation.com | www.hydrogen-expo.com

Contact:

VON ARDENNE GmbH

Ingo Bauer

+49 351 2637 9000

presse@vonardenne.com

www.vonardenne.com

Weil Technology GmbH

Felicitas Ledig

+49 7631 1809 399

f.ledig@weil-technology.com

www.weil-technology.com

ZELTWANGER Group

Benjamin Rilling

+49 7071 3663-119

B.Rilling@zeltwanger.de

www.zeltwanger.de